Lignosulfonate(lignosulphonate) (often abbreviated as LS) were one of the first dispersants added as an admixture to concrete. Lignosulfonates have been used since the 1930s as plasticizers or water reducers. Mixed with concrete, their use has afforded the beneficial effects of retarding the setting time and reducing the amount of mixing water required.

The only lignin products obtained from a pulping process that have found a vast range of applications up to now are lignosulfonates. These are non-hazardous materials with excellent properties that are used as binders, emulsifiers and dispersants for a great variety of materials. As inexpensive components in binders, lignosulfonates are commonly used for commodities like coal briquettes, ceramics, briquetting of mineral dust, and the production of plywood or particle boards. Their ability to retain moisture and suppress dust makes them a useful tool for construction works, gravel roads, airports and sports facilities.

As an anti-settling agent that also prevents lumping, lignosulfonates are used in concrete mixtures, ceramics, gypsumboard production and for leather tanning. Lignosulfonates provide flowability and plasticity to cement. This is a replacement for more expensive materials that provide set retardation such as superplasticisers, gluconates and gluconic acid. Wet-process Portland cement mills utilise lignosulfonates to increase the solids content of raw slurries. Lignin-based concrete additives are in demand and can be worth as much as $1.05–$1.32/L as an aqueous solution (Holladay et al., 2007). Sulfur-free lignin such as soda lignin has also been shown to improve flowability of mortar (Nadif et al., 2002). Lignosulfonates can also stabilise emulsions of immiscible fluids like asphalt emulsions, pesticide preparations, pigments and dyes.

Due to their low toxicity, they can be used as binders in animal feed and thereby improve the feed properties of pellets. In addition, lignosulfonates show the ability to keep micronutrients in solution which is useful for micronutrient transport or as a cleaning and decontaminating agent in water and soils (Nadif et al., 2002; Calvo-Flores and Dobado, 2010

Furthermore, greater workability of plastic concrete during its placement in formworks and increased air entrainment have resulted from their use. As by-product of the pulping industry, lignosulfonates are of low price and despite their limited performance they find a large field of applications for improving the quality of concrete.

Lignosulfonates, or sulfonated lignin are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite pulping.

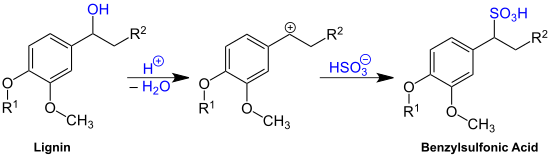

Most delignification in sulfite pulping involves acidic cleavage of ether bonds, which connect many of the constituents of lignin. The electrophilic carbocations produced during ether cleavage react with bisulfite ions (HSO3−) to give sulfonates. R-O-R’ + H+ → R+ + R’OHR+ + HSO3− → R-SO3H

The primary site for ether cleavage is the α-carbon (carbon atom attached to the aromatic ring) of the propyl (linear three carbon) side chain. The following structures do not specify the structure since lignin and its derivatives are complex mixtures: the purpose is to give a general idea of the structure of lignosulfonates. The groups R1 and R2 can be a wide variety of groups found in the structure of lignin. Sulfonation occurs on the side chains, not on the aromatic ring like in p-toluenesulfonic acid.

Lignosulfonate have very broad ranges of molecular mass (they are very polydisperse). A range of from 1000–140,000 da has been reported for softwood lignosulfonates with lower values reported for hardwoods.